Hazelett casting technology - animations

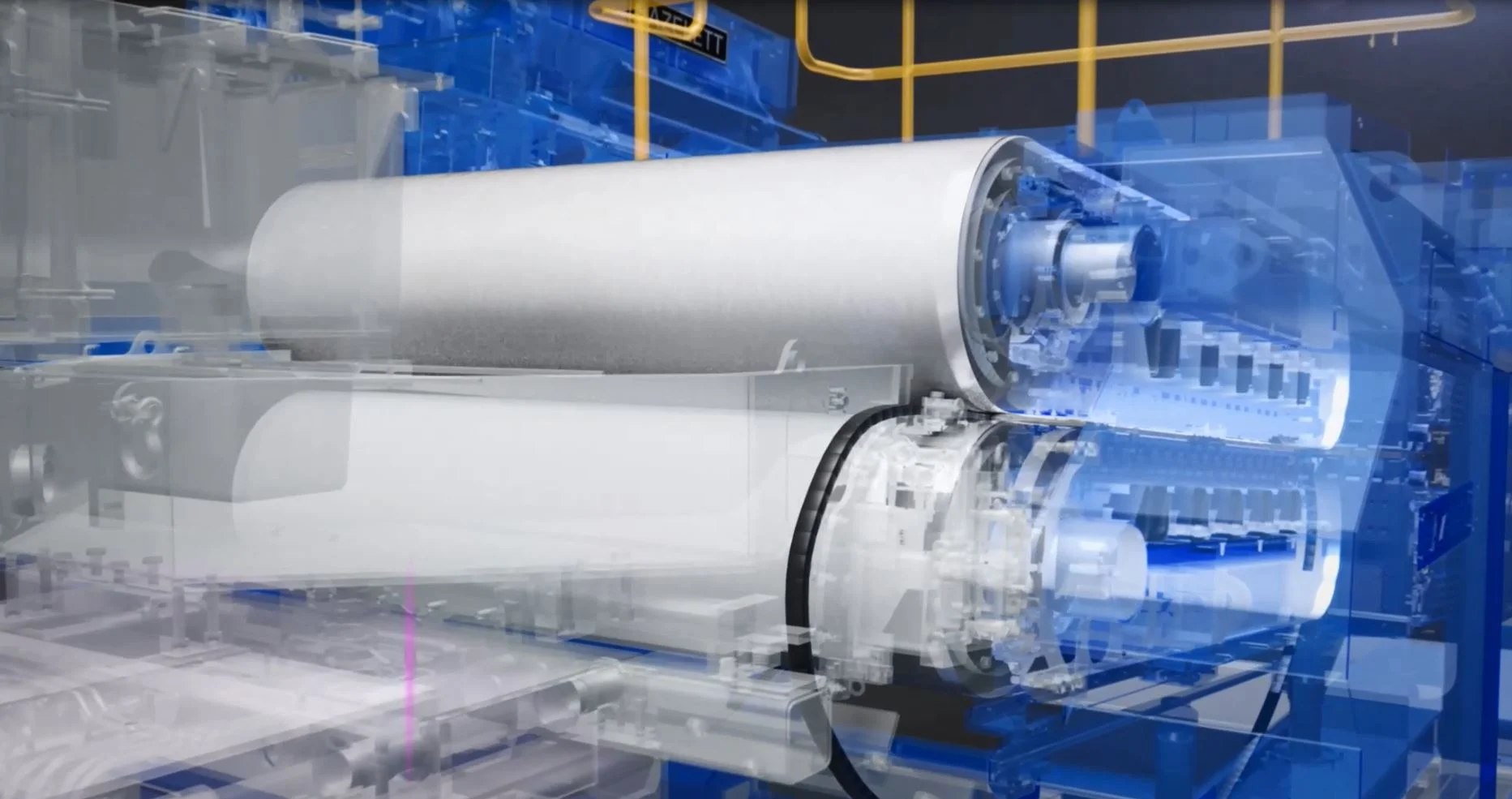

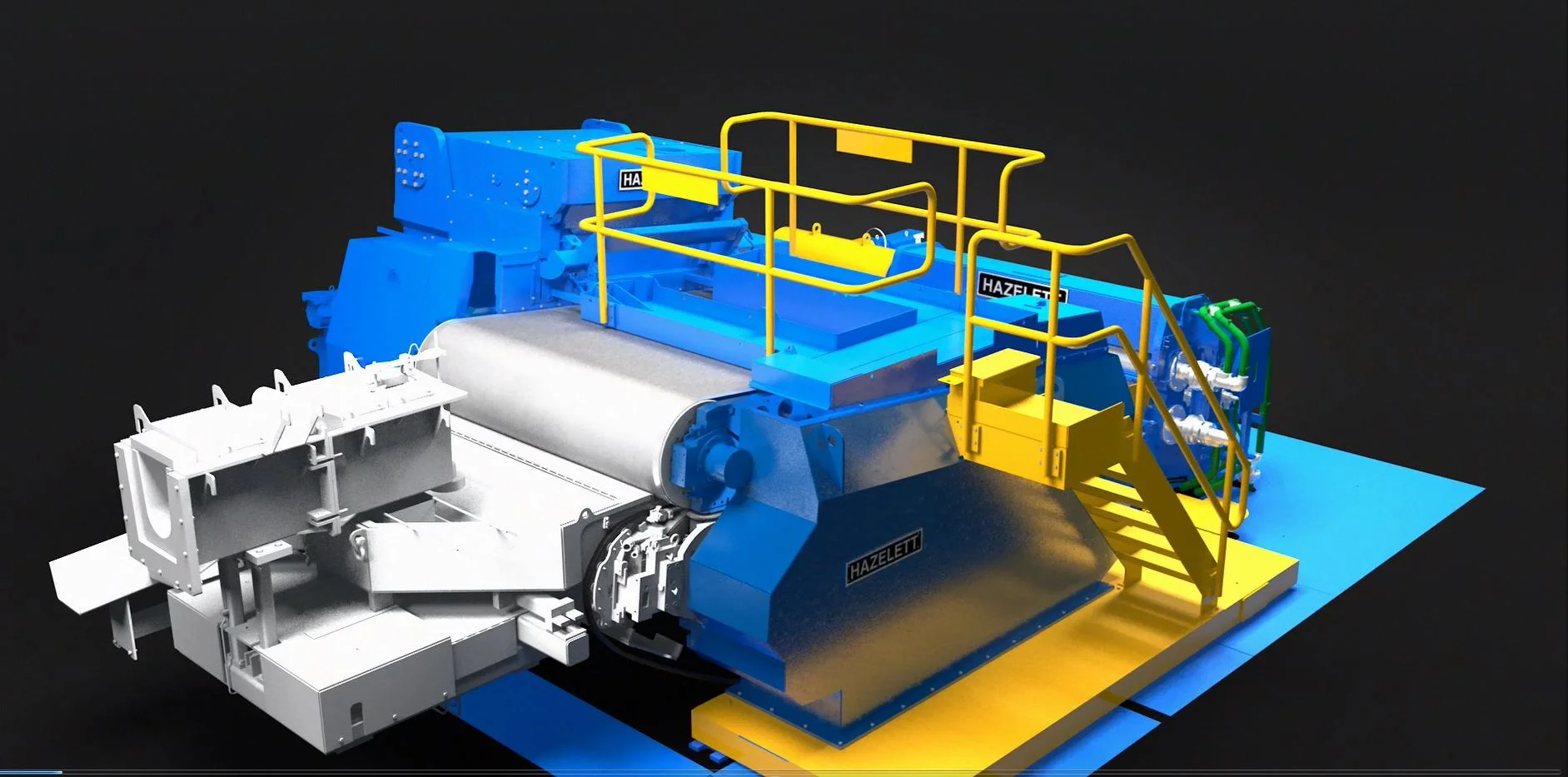

Hazelett twin-belt casting machine for aluminum

The Hazelett® twin-belt caster features a straight, parallel moving mold using belts as mold surfaces. The moving belts define the upper and lower mold surfaces. Chains of moving edge blocks form the sides of the mold.

Molten metal is introduced between the belts and is solidified as it travels within the moving mold. Solidification occurs as heat is transferred to water on the backside of the belts. Heat transfer can be adjusted and controlled to achieve high production rates and superior strip quality.

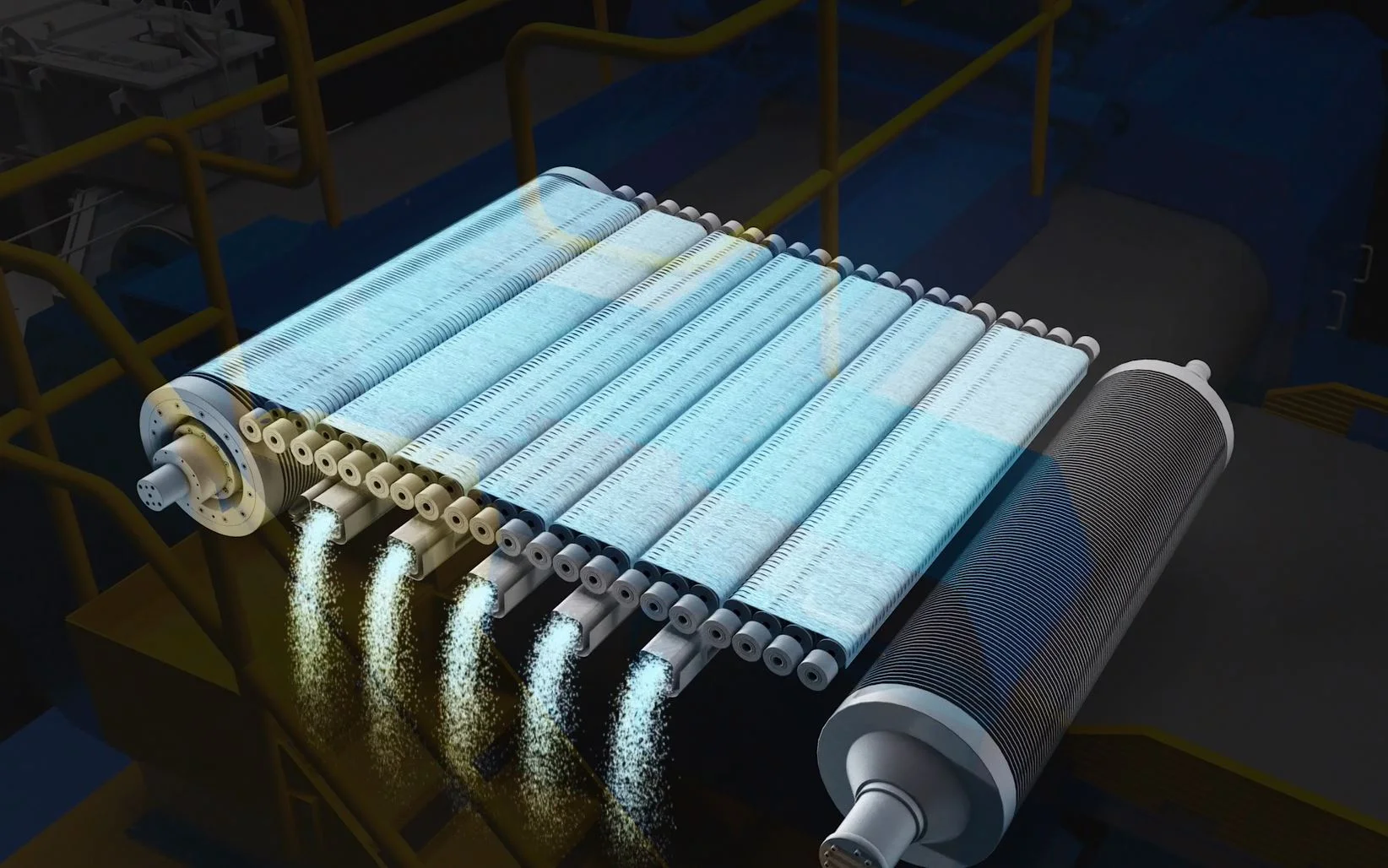

Behind the belts, precisely machined finned back-up rolls support the belts while allowing water to pass. Magnetic back up rolls, positioned in the first part of the mold, counteract belt instability due to thermal bending induced by high heat fluxes.