Hazelett zinc casters produce extremely versatile zinc strip used for countless products, including the US penny and Canadian coins.

Our zinc technology is enduring - some of our casters have been in operation for over 50 years.

Customers worldwide are using the Hazelett zinc casters to continuously cast zinc slab/strip in a variety of thicknesses up to 1350 mm wide. Depending on the applications, this strip is then rolled, drawn, shaped, slit, and otherwise machined into the shape required.

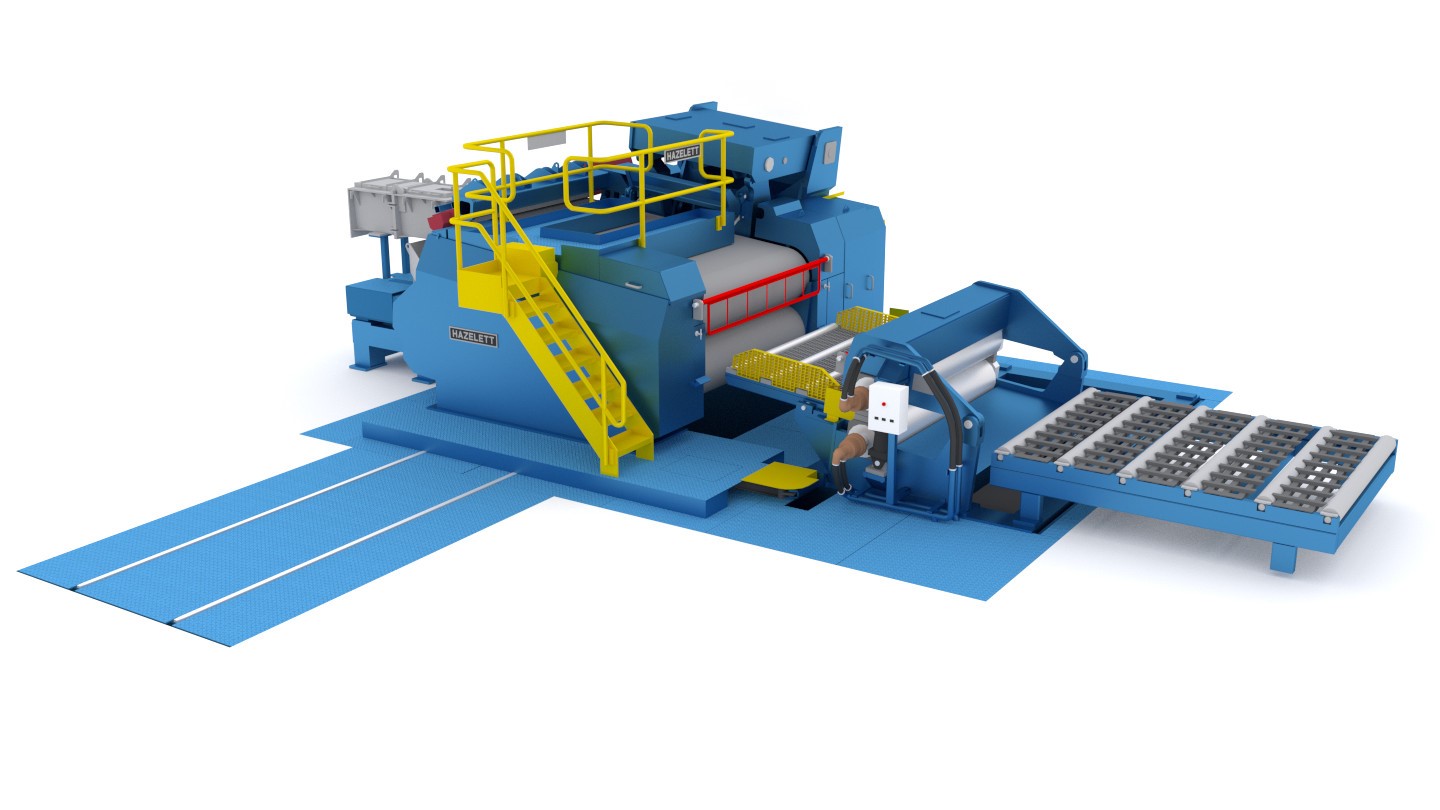

Hazelett zs1320 zinc strip caster

general specifications

Maximum width range: 250 mm - 1320 mm

Casting rate (hourly): 36 tonnes per meter of width

Production capacity: 20,000 - 150,000 tonnes per year

Alloys cast: copper zinc, copper titanium zinc, lead cadmium zinc

benefits

- Highest production rates of any continuous casting method

- Lower conversion cost

- Lower energy consumption compared to other casting methods

- Lower overall production costs

- Lower total cost of ownership - High quality cast zinc

- Uniform surface solidification rates

- Excellent surface quality - Continuous technology development

- Highly reliable continuous operation

- Flexible gauge range

- Flexible alloy capability

- Reduced material inventory